Drop Protection Cuff

In many bathrooms, pipes lead through the wall and the tiles to the tap. To avoid moisture damage, the pipe penetrations must be sealed. Specially designed for wall-mounted taps (hot/cold), our drop protection cuff ensures that everything stays watertight.

No material fatigue with our sealing collars

Changing from hot to cold and vice versa keeps the pipe system in the wall in constant motion. With many competing products, material fatigue occurs over the years. This can cause tiny leaks through which moisture can penetrate the substrate, damaging the fabric of the building. With our especially durable cuff, this will not happen to you.

Sealing collars also for pipe and cable penetrations

If a pipe leading through the wall is exposed during restoration, subsequent sealing may be necessary, depending on the installation situation. Thanks to its simple installation, our drop protection cuff is also ideally suited for this purpose.

Corner Tape

The corner tape is used in conjunction with sealing membranes to create waterproof wall/wall and wall/floor transitions. You need it, for example, to seal shower channels to the wall and the floor or to protect the corner area from above from penetrating moisture. For installation purposes, you can easily fold it at a 90° angle. 45° are also possible.

The corner adhesive tape serves as a connecting link and supplement to the sealing membranes. To ensure absolute watertightness, you must work with overlaps. As the tape is 100 mm wide and 100% fleece-free, it offers you enough space on both sides to apply the membranes. Thanks to its elasticity, the corner tape can be fixed without tension. This ensures maximum adhesion.

Cut-Resistant Joint Sealant

Organic substances such as skin and hair attack the joints in the bathroom. This makes conventional joint sealants like silicone brittle over time. Hairline cracks develop, which can lead to the formation of mould. For this reason, the joints must be checked annually for leaks and serviced if necessary.

Our cut-resistant joint sealant fulfils several functions in this respect. Firstly, it protects the tub sealing tape against unintentional cutting when changing the joint. Secondly, you save a lot of time during dismantling, since you only have to pull the round cord out of the joint. This is really simple due to the very high tear strength of 100 kg and easy to handle. An advantage here is the 2-flank adhesion, which makes "getting it out" much easier than with 3-flank adhesion.

The joint sealant is compressible. The material opens behind the tile and protects the substrate optimally towards the front. The joint remains flexible and elastic and ensures maximum moisture protection even at fluctuating temperatures.

Tub Sealing Tape

Our double-sided self-adhesive, fleece-free tub sealing tape provides a permanent invisible moisture barrier between tub and wall or tub and floor. It meets all the requirements of DIN 18534 and has passed all tests related to this.

Working with the tub sealing tape should not present you with any major challenges. Installation is possible as long as the temperature does not fall below 0°C. In the first step, you fix the approx. 20 mm wide red adhesive strip around the tub so that the non-adhesive base quantity of black foam protrudes above the tub. Then you place the corners for the wall or floor connection. Now all you have to do is remove the protective film from the back, position the tub and press the tape to the wall or floor.

Base Sealing Tape

When showering and bathing, steam can form, which condenses into water on the walls. From there it continues to flow towards the ground and can penetrate it if the sealing is insufficient. As required by DIN 18534, we recommend that watertight wall/floor transitions be installed in areas exposed to spray and drain water. Our base tape is best suited for this purpose.

Unlike the similar-looking corner sealing tape, the front of the base sealing tape is half-covered with fleece. This ensures the good adhesion of subsequently applied wall coverings. The base tape is fitted in the same way as the corner tape. You just have to make sure that you place the fleece-covered area on the wall and the fleece-free area on the floor.

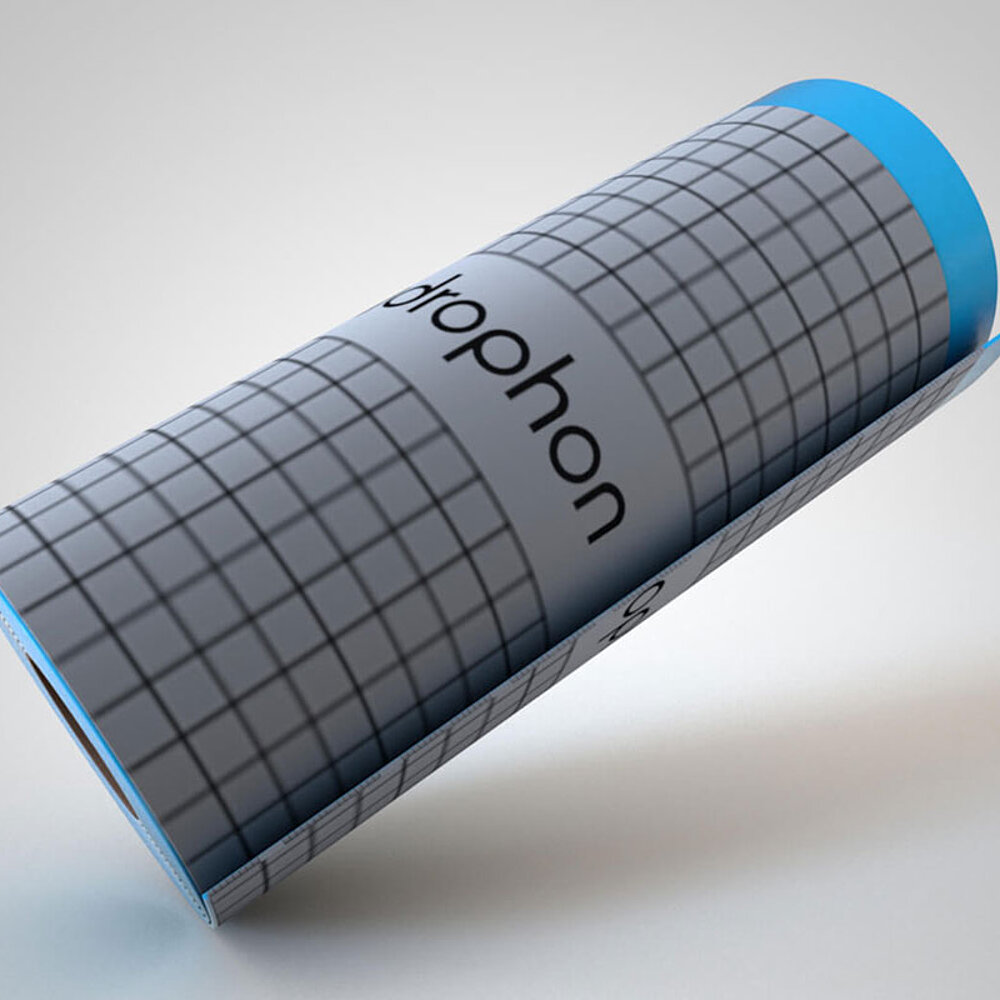

Sealing Membrane

Our self-adhesive sealing membrane, which acts like a sealant, is an efficient alternative to liquid sealants based on dispersion, cement or synthetic resin, as well as to film sheeting. Unlike these materials, it achieves an adhesive strength of at least 20 tons per square metre within seconds. This makes time-consuming drying times a thing of the past.

The adhesive adapts perfectly to walls and floors. It adheres to drywall, wooden substructures, walls bound with lightweight plaster, as well as all substrates standardised according to DIN 18534. The 0.5 mm thick foam layer compensates for small irregularities and ensures that the sealing membrane fits perfectly.

The 50 mm wide adhesive edge/overlap ensures capillary protection and complies fully with the current standard. This capillary protection zone with its high elasticity has even been patented. Prefabricated for gluing on additional membranes, the sealing membrane is highly variable in its potential use. Thanks to its resistance to chemicals and alkalis, it is extremely durable. Directly after gluing, you can apply any type of wall covering, for example tiles.

While conventional sealing membranes have a width of one metre, our self-adhesive version is only 500 mm wide. This corresponds to an average arm length. This makes handling easier and prevents installation errors. Such errors would be particularly annoying, as it is not possible to move the sealing membranes afterwards. With us: fixed means fixed.

Since the membranes are suitable for overlapping gluing, there is no residue or waste when shortening. With fleece-free sealing membranes, you can also continue to use short pieces without difficulty. This makes the sealing membrane extremely sustainable and cost-efficient. For a perfect finish at the edges, there is a 100 mm wide finishing strip that you simply stick onto the fleece-free zone.

Drop Protection Cuff

In many bathrooms, pipes lead through the wall and the tiles to the tap. To avoid moisture damage, the pipe penetrations must be sealed. Specially designed for wall-mounted taps (hot/cold), our drop protection cuff ensures that everything stays watertight.

No material fatigue with our sealing collars

Changing from hot to cold and vice versa keeps the pipe system in the wall in constant motion. With many competing products, material fatigue occurs over the years. This can cause tiny leaks through which moisture can penetrate the substrate, damaging the fabric of the building. With our especially durable cuff, this will not happen to you.

Sealing collars also for pipe and cable penetrations

If a pipe leading through the wall is exposed during restoration, subsequent sealing may be necessary, depending on the installation situation. Thanks to its simple installation, our drop protection cuff is also ideally suited for this purpose.

Request a hy efficiency kit

Corner Tape

The corner tape is used in conjunction with sealing membranes to create waterproof wall/wall and wall/floor transitions. You need it, for example, to seal shower channels to the wall and the floor or to protect the corner area from above from penetrating moisture. For installation purposes, you can easily fold it at a 90° angle. 45° are also possible.

The corner adhesive tape serves as a connecting link and supplement to the sealing membranes. To ensure absolute watertightness, you must work with overlaps. As the tape is 100 mm wide and 100% fleece-free, it offers you enough space on both sides to apply the membranes. Thanks to its elasticity, the corner tape can be fixed without tension. This ensures maximum adhesion.

Request a hy efficiency kit

Cut-Resistant Joint Sealant

Organic substances such as skin and hair attack the joints in the bathroom. This makes conventional joint sealants like silicone brittle over time. Hairline cracks develop, which can lead to the formation of mould. For this reason, the joints must be checked annually for leaks and serviced if necessary.

Our cut-resistant joint sealant fulfils several functions in this respect. Firstly, it protects the tub sealing tape against unintentional cutting when changing the joint. Secondly, you save a lot of time during dismantling, since you only have to pull the round cord out of the joint. This is really simple due to the very high tear strength of 100 kg and easy to handle. An advantage here is the 2-flank adhesion, which makes "getting it out" much easier than with 3-flank adhesion.

The joint sealant is compressible. The material opens behind the tile and protects the substrate optimally towards the front. The joint remains flexible and elastic and ensures maximum moisture protection even at fluctuating temperatures.

Request a hy efficiency kit

Tub Sealing Tape

Our double-sided self-adhesive, fleece-free tub sealing tape provides a permanent invisible moisture barrier between tub and wall or tub and floor. It meets all the requirements of DIN 18534 and has passed all tests related to this.

Working with the tub sealing tape should not present you with any major challenges. Installation is possible as long as the temperature does not fall below 0°C. In the first step, you fix the approx. 20 mm wide red adhesive strip around the tub so that the non-adhesive base quantity of black foam protrudes above the tub. Then you place the corners for the wall or floor connection. Now all you have to do is remove the protective film from the back, position the tub and press the tape to the wall or floor.

Request a hy efficiency kit

Base Sealing Tape

When showering and bathing, steam can form, which condenses into water on the walls. From there it continues to flow towards the ground and can penetrate it if the sealing is insufficient. As required by DIN 18534, we recommend that watertight wall/floor transitions be installed in areas exposed to spray and drain water. Our base tape is best suited for this purpose.

Unlike the similar-looking corner sealing tape, the front of the base sealing tape is half-covered with fleece. This ensures the good adhesion of subsequently applied wall coverings. The base tape is fitted in the same way as the corner tape. You just have to make sure that you place the fleece-covered area on the wall and the fleece-free area on the floor.

Request a hy efficiency kit

Sealing Membrane

Our self-adhesive sealing membrane, which acts like a sealant, is an efficient alternative to liquid sealants based on dispersion, cement or synthetic resin, as well as to film sheeting. Unlike these materials, it achieves an adhesive strength of at least 20 tons per square metre within seconds. This makes time-consuming drying times a thing of the past.

The adhesive adapts perfectly to walls and floors. It adheres to drywall, wooden substructures, walls bound with lightweight plaster, as well as all substrates standardised according to DIN 18534. The 0.5 mm thick foam layer compensates for small irregularities and ensures that the sealing membrane fits perfectly.

The 50 mm wide adhesive edge/overlap ensures capillary protection and complies fully with the current standard. This capillary protection zone with its high elasticity has even been patented. Prefabricated for gluing on additional membranes, the sealing membrane is highly variable in its potential use. Thanks to its resistance to chemicals and alkalis, it is extremely durable. Directly after gluing, you can apply any type of wall covering, for example tiles.

While conventional sealing membranes have a width of one metre, our self-adhesive version is only 500 mm wide. This corresponds to an average arm length. This makes handling easier and prevents installation errors. Such errors would be particularly annoying, as it is not possible to move the sealing membranes afterwards. With us: fixed means fixed.

Since the membranes are suitable for overlapping gluing, there is no residue or waste when shortening. With fleece-free sealing membranes, you can also continue to use short pieces without difficulty. This makes the sealing membrane extremely sustainable and cost-efficient. For a perfect finish at the edges, there is a 100 mm wide finishing strip that you simply stick onto the fleece-free zone.

Request a hy efficiency kit